The Evolution of Bearings

The Evolution of Bearings

Blog Article

Imagine a world where machinery runs smoother, lasts longer, and requires less maintenance than ever before. As industries strive for efficiency and sustainability, bearings play a crucial role in achieving these goals. With the rise of advanced materials and smart technologies, the future of bearings is set to transform dramatically. Predicting the future of bearings with Aubearing reveals insights into how these innovations are reshaping the landscape of motion and energy management.

The Evolution of Bearings

Bearings have been fundamental components in machinery for centuries, allowing for smooth rotational or linear movement. Traditional bearings, often made from steel, have served industries well. However, they come with limitations, including susceptibility to wear and corrosion. The need for improved performance has sparked interest in alternative materials and designs.

Ceramic Bearings: A Game Changer

Ceramic bearings are at the forefront of this evolution. Made from materials like silicon nitride, they offer significant advantages over their steel counterparts. For instance, ceramic bearings are lighter, have lower friction coefficients, and can withstand higher temperatures. These properties make them ideal for high-performance applications, such as aerospace and motorsports, where every gram and degree count.

[IMAGE]

Integration of Smart Technology

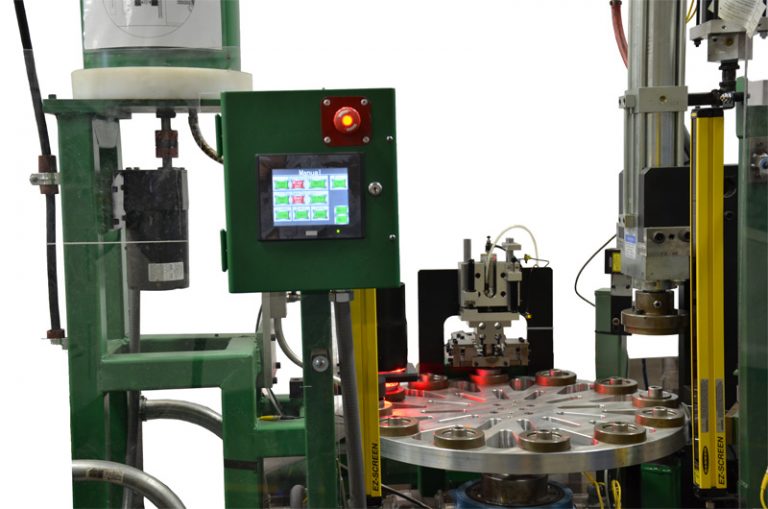

Another pivotal development in the bearing industry is the integration of smart technology. Bearings equipped with sensors can provide real-time data on their condition, performance, and environment. This capability allows for predictive maintenance, where potential failures can be addressed before they lead to costly downtime. For instance, a manufacturing plant can monitor the vibration levels of its machinery and schedule maintenance based on actual wear patterns rather than on a fixed schedule.

Environmental Considerations

As the world shifts towards more sustainable practices, the bearing industry is not left behind. The production and disposal of traditional bearings often involve materials and processes that can harm the environment. In contrast, advancements in ceramic bearings not only reduce energy consumption but also enable more sustainable manufacturing processes. For example, the reduced weight of ceramic bearings can lead to lower fuel consumption in vehicles, contributing to greener transportation solutions.

The Role of Customization

Customization is becoming increasingly important in the bearing market. As industries become more specialized, the demand for tailored solutions rises. Manufacturers that offer customized bearings designed for specific applications can significantly enhance performance and efficiency. This trend is particularly evident in industries such as renewable energy, where unique bearing solutions are necessary for wind turbines and solar tracking systems.

Challenges Ahead

Despite these advancements, several challenges remain. The high cost of advanced materials and manufacturing processes can be a barrier for some businesses. Additionally, the transition to new materials requires a shift in design and engineering practices, which can take time and investment. However, as technological advancements continue and research into materials science progresses, these challenges are likely to be addressed.

Conclusion

The future of bearings is bright, filled with innovation and promise. With the adoption of materials like ceramics, integration of smart technologies, and a focus on sustainability, the industry is poised for transformation. Companies like Aubearing are at the forefront of this change, driving the conversation around the evolution of bearings and their applications. As we look ahead, the advancements in this field will undoubtedly lead to improved efficiencies and capabilities across multiple sectors.

Report this page